Client: Renu Architects, Bengaluru

Project Type: Modular Kitchen Renovation – 4BHK Urban Apartment

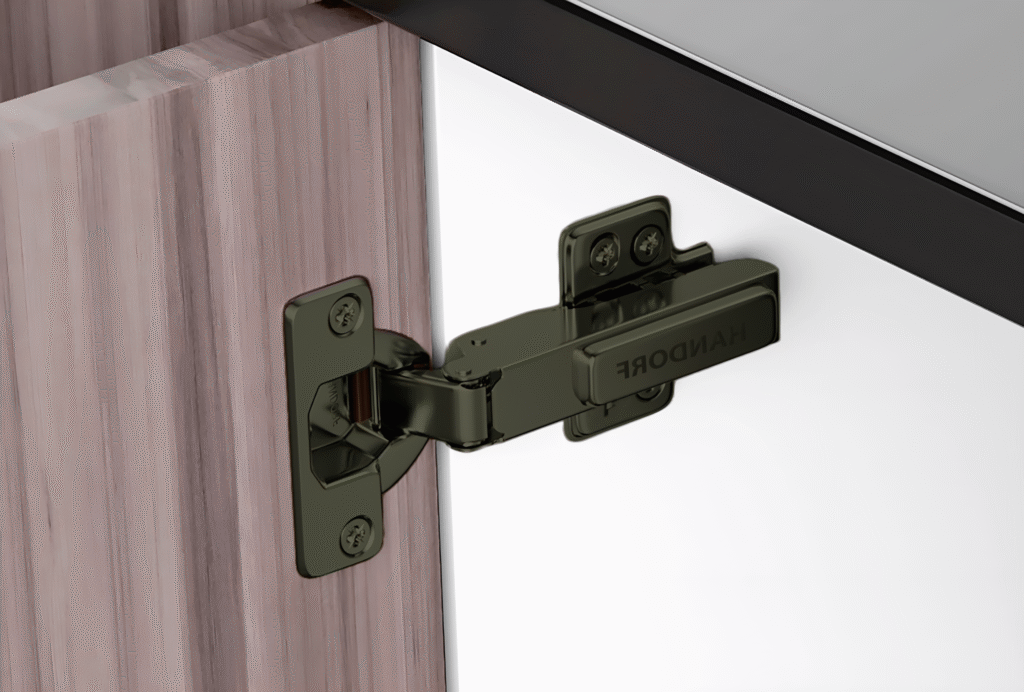

Products Used: Handorf Cabinet Handles (Brushed Nickel Finish), Designer Knobs (Matte Black)

Objective: Improve ergonomic access and long-term durability of kitchen cabinetry hardware for a multi-generational household

The Problem: Style without Functionality

In early 2024, Renu Architects took on a full kitchen redesign for a 4BHK apartment in a high-rise Bengaluru complex. The brief was simple yet demanding: deliver a sleek modular kitchen that catered to both elderly users and young professionals in the same family.

The cabinetry was well-planned, but standard off-the-shelf handles quickly became a problem:

- Shallow grip profiles made tall pantry and corner units hard to access

- Uneven handle sizing disrupted the visual flow of the kitchen

- Inferior finishes showed signs of tarnish within months due to Bengaluru’s humidity

- Installation misalignments from inconsistent drilling guides created rework headaches

The architect needed a hardware partner that could match the project’s premium aspirations while solving these usability issues.

The Handorf Solution: Ergonomics Meets Durability

Handorf was brought in to supply cabinet handles and knobs engineered for Indian conditions. The specification included:

- Brushed nickel finish handles with 160mm center-to-center fitting — ideal for modular consistency

- Matte black knobs for overhead cabinets — adding contrast while enhancing grip

- Rust-resistant coating to withstand coastal humidity and reduce maintenance

- Pre-aligned templates to support flawless installation by contractors

The hardware wasn’t just a finishing touch — it became integral to the experience of using the kitchen daily.

Implementation & Impact

Once installed, the transformation was immediate and measurable. The ergonomic curve and depth of the handles offered seamless grip even for wet hands, elderly fingers, or hurried morning routines.

Key Outcomes:

- 30% reduction in installation time due to standardized templates and pre-measured sizes

- Zero rust or tarnish observed after 6 months of daily use

- Improved accessibility across deep drawers, corner units, and high-mounted cabinets

- Design continuity achieved across all zones of the kitchen — aligning with the architect’s minimalist vision

Client Feedback

“We’ve worked with many hardware vendors, but Handorf stood out for its thoughtful detailing and support during execution. Their handles not only elevated the aesthetic but solved real-world usability issues for a multi-generational household. No callbacks, no rusting, and happy clients — what more could we ask for?”

— Ritu Bansal, Principal Architect, Renu Architects

Conclusion

The success of this project demonstrates how the right hardware can significantly enhance both the functionality and longevity of modular kitchens in Indian homes. In spaces where multiple generations interact daily, cabinet handles and knobs are not just finishing elements — they play a critical role in usability, safety, and design continuity.

By integrating Handorf’s premium cabinet hardware, the project not only met the client’s aesthetic expectations but also delivered long-term performance and user comfort. For architects, interior designers, and developers, this case reinforces the importance of specifying hardware that aligns with both the technical and emotional needs of the end user.

Handorf continues to set the benchmark for precision, durability, and design excellence in India’s evolving modular kitchen landscape.